BlogSemiconductor EDA: How focusing on User Experience opened up a new market

An open Electronic Design Automation project has uniquely addressed traditional chip design usability complexity. In doing so, they demonstrate how designing for the users’ experience opened up a new, unserved market.

June 6, 2022I began my engineering career in semiconductors in 1997, in 0.42μ (420 nm) technology. I realize that last part sounds overly numerical, but in this industry, referencing a minimum feature size is as good as conveying your age like rings on a tree trunk. Everything about designing and taping out a chip was complex, time consuming, and expensive. As chip performance metrics have improved exponentially in almost every category since then, the tooling used to design a chip itself has also improved a great deal…though it remains complex and expensive.

Commercial EDA and the expertise gap

Electronic Design Automation (EDA) is a class of enterprise software used by engineers to design the chips that find themselves in cars, phones, computers, and just about everything else except stationary furniture. Commercial EDA tools purchased by major semiconductor companies are feature-rich, highly configurable, underpinned by Ph.D.-level research, and designed by hardware engineers, for hardware engineers. They are sophisticated, and built upon algorithms that make possible the chip performance we see today. However, from a user experience (UX) point of view, using EDA software has always been highly complex. Each engineer required days or weeks of training from the EDA vendor. On top of the software’s own complexity, managing automation of EDA-related tasks is custom-scripted by each semiconductor company. This glue is an elaborate framework of scripts and interstitial tooling that automate otherwise manual, tedious tasks. In other words, nothing about traditional EDA has been turnkey from the viewpoint of the user experience and knowledge requirements.

Consider the number of specialized engineers required for a project, their EDA tools training, the EDA software itself, and the hard costs of IT infrastructure. It’s no wonder that historically we haven’t seen near the number of chip startups as software startups. The expertise gap and entry costs are excessive, before designing the chip’s functionality itself. Only companies with a large scale business case and significant funding can afford to innovate.

Chip design takes a big leap

Fast forward to 2022 where semiconductor production technology has leaped 100 fold to 0.005μ (5 nm). In addition, design technology has changed. Non-commercial, community-supported tooling, frameworks, and libraries in commercial software development is a proven sustainable model. Now in chip hardware design, like in pure software development, we see growing momentum to embrace open EDA tooling that is moving beyond the realm of hobbyists and viable as an alternative to commercial EDA.

One key project has specifically addressed the user experience of chip design in such a way that it enables an expanded user base due to the simplified user experience, ultimately eliminating competitive barriers to custom chip design.

This OpenROAD project, “attacks the barriers of Cost, Expertise and Uncertainty (i.e., Risk) that block the feasibility of hardware design in advanced technologies.” The expertise gap in standard chip design, as OpenROAD points out, has “blocked system designers’ access to advanced technology.” In doing so, it has blocked innovation and competitiveness.

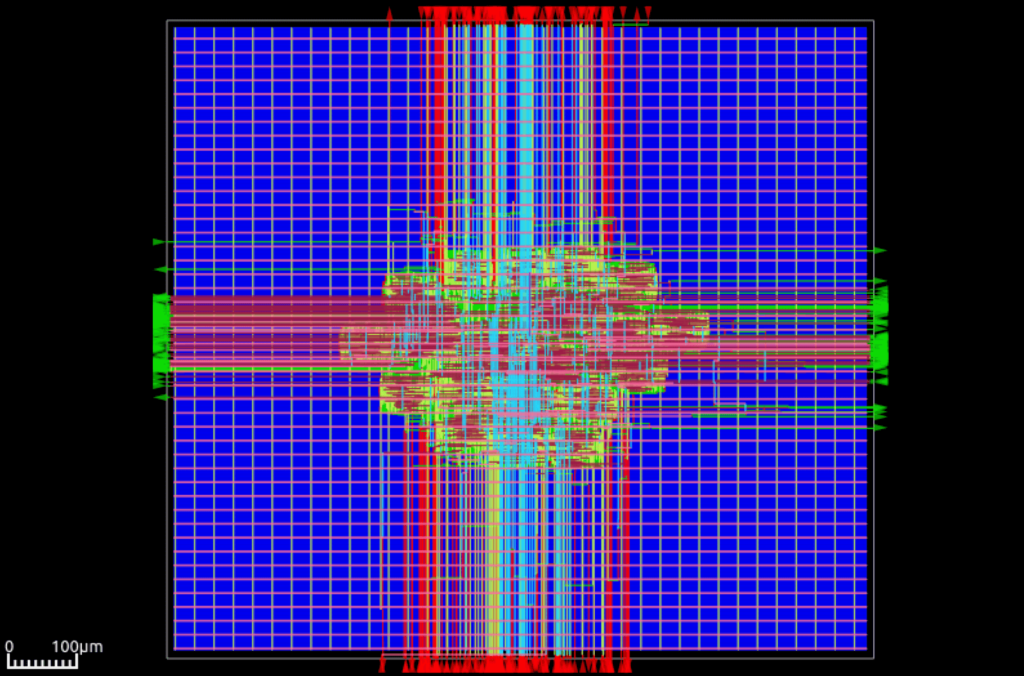

UX design for software enables usable products for humans that fit their needs, expectations, and models of thinking. OpenROAD uniquely addresses chip design UX by minimizing the need for human interaction altogether. Their objective is to completely automate the process, going from the functional description of the chip (called RTL), and producing the taped-out physical design files (called GDS). They have greatly simplified the UX, eliminating key user steps and the high costs and expertise barriers evident today. OpenROAD makes a tradeoff in favor of usability versus complete optimization.

UX as a competitive edge for chip suppliers

For the time being, most established semiconductor companies will continue to use commercial EDA solutions from the established vendors, as they require a high level of configurability and optimization. OpenROAD’s objective is not to unseat traditional EDA. Instead, by transforming the user experience of the chip design process, they will address and open an entirely new, underserved market that cannot use traditional EDA and methods. By making the usability tradeoff, the expertise gap is reduced, and with that the operating, infrastructure, and design costs as well. Companies who couldn’t have entertained such innovation previously now have this option. Couple that with the RISC-V free and open microprocessor ISA initiative, and we have the critical mass to seed new SoC innovation.

Tying it together

The lesson can apply to the semiconductor industry as a whole. Semiconductor companies sell more than chips – they deliver complete solutions that include software to support their hardware products and enable customer product development. Leading edge UX design principles have been a mainstay for successful software companies with truly differentiated products that have measurable competitive advantage. Likewise, adoption of best-in-class UX design can establish a competitive advantage for semiconductor companies by accelerating customers’ time-to-ramp to production and creating a frictionless experience during product development. When customers experience an ecosystem of intuitive, easy-to-use software that supports their own time-to-market efforts, the semiconductor vendor further cements themselves as a solution partner.

Photo by Laura Ockel on Unsplash

Don't miss out on the latest insights and trends in UX design and AI research! Subscribe to our newsletter.